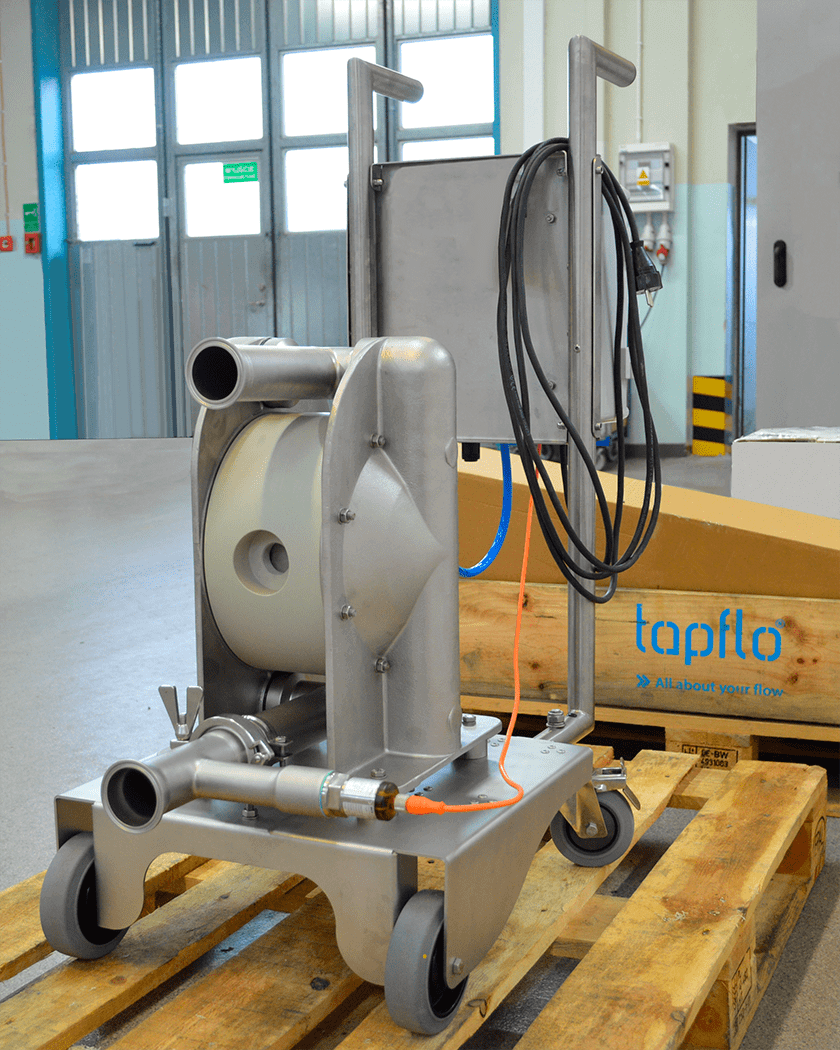

T220 metal diaphragm pump mounted on an industrial trolley, designed for the final customer from pharmaceutical industry.

This unit helps with removing the leftovers of cleaning solutions from CIP (Cleaning-in-Place) system. The built-in automation system has two functions:

- Detecting the presence of liquid in the suction line

- Switching the pump off during dry run operation

The pump itself is built with ingenious simplicity – we use approximately 70% fewer parts than our competitors use to build similar sized pumps!

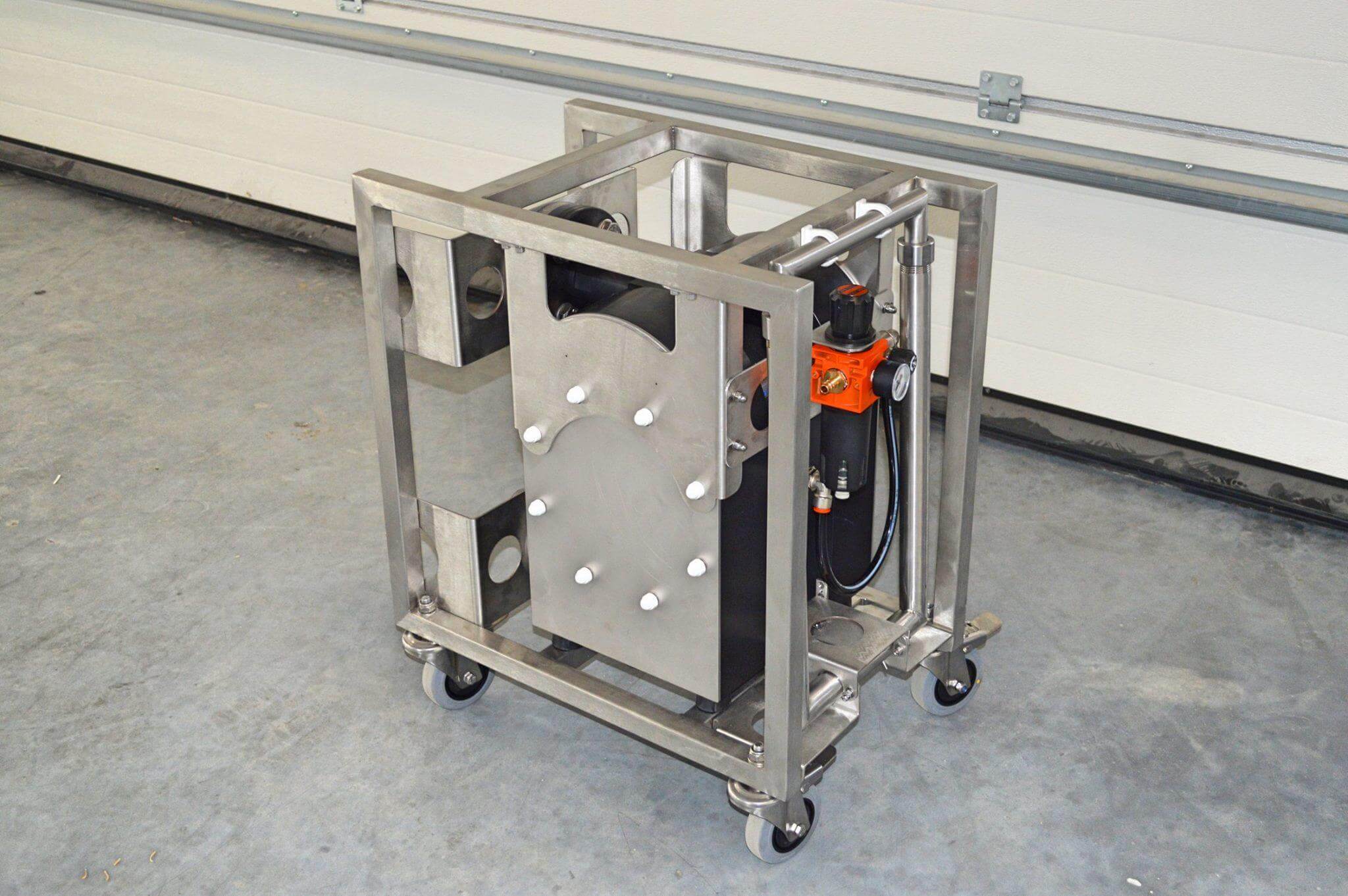

CTH D FOR THE BEVERAGE INDUSTRY

CTH D pump assembled on an M size trolley equipped with a frequency inverter, designed for beverage industry. The customer requested a “Plug and Play” solution characterized by the following features: sanitary design, easiness of use, mobility, compactness, simplicity of control. The unit fully meets these requirements.

The CTH D pump itself is supplied with an electro-polished casing and internals with excellent surface finishing which makes it a perfect solution for hygienic duties, in this case beverage industry, where clean- and drain-ability are crucial.

The mobility of the unit helps with working in different locations and makes carrying the pump around unnecessary.

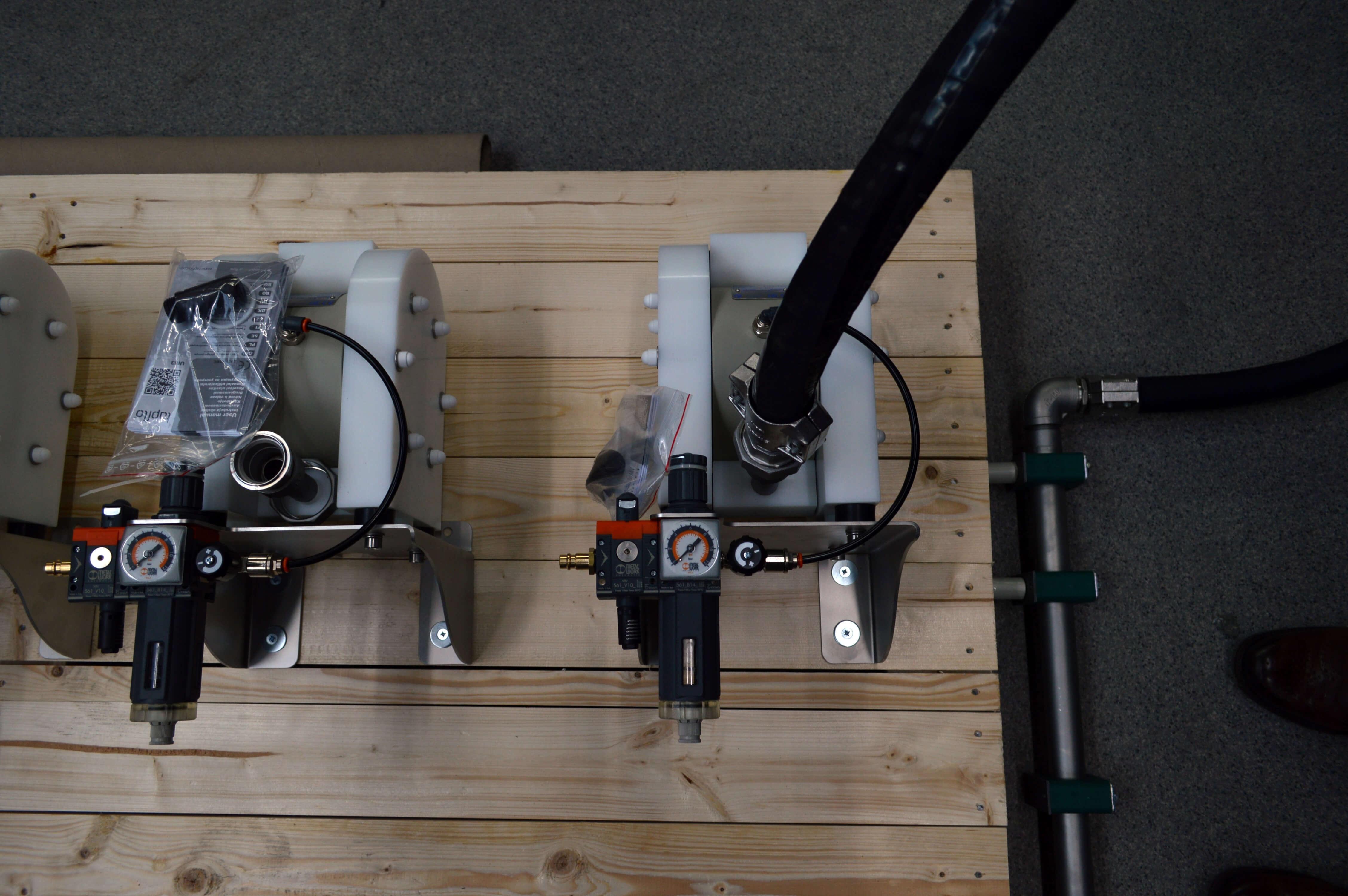

PUMP FOR COUGH SYRUP

TX444 S the largest in Tapflo aseptic diaphragm pumps series.

This unit finds use in pharmaceutical industry to meet high flow requirements when transferring viscous mixture of glucose syrup and honey during cough syrup production.

Owing to its special design TX444 meets EHEDG regulations. The EHEDG (European Hygienic Engineering & Design Group) certificate guarantees that the design is according to the hygienic guidelines. Furthermore the pump is clean ability tested, which means bacteria does not grow in the pump after cleaning and draining procedure.

PUMP FOR COUGH SYRUP

TX444 S the largest in Tapflo aseptic diaphragm pumps series.

This unit finds use in pharmaceutical industry to meet high flow requirements when transferring viscous mixture of glucose syrup and honey during cough syrup production.

Owing to its special design TX444 meets EHEDG regulations. The EHEDG (European Hygienic Engineering & Design Group) certificate guarantees that the design is according to the hygienic guidelines. Furthermore the pump is clean ability tested, which means bacteria does not grow in the pump after cleaning and draining procedure.

EMERGENCY SITUATIONS PUMPS

The key features of the design are:

- mobility – the unit weighs only 110 kg (242.5 lbs).

- compactness – the unit is equipped with Camlock connections and air treatment system which does not protrude out of the frame.

- explosion proof – the unit can be used in ATEX Ex II 3G Ex IIB T4 zone.

- reinforced stainless steel construction that protects the pump from damage during the rescue operation.

WASHING LINE SYSTEMS: CTV AND T50 PUMPS

The units are used on the washing line of the manufacturer, that produces aircraft parts. As a solution we proposed CTV pumps, they are used to circulate and filter washing liquids - mainly sodium hydroxide.

In the same project T50 pumps are used for unloading chemical additives from the barrels and then dosing them to washing baths. Tapflo main goal was to deliver a solution that would provide an easy and safe operation. At the same time we met the important requirement of our customer - footprint reduction.

SANITARY PUMP FOR MUSHROOMS TRANSFER

T825 ST-5SF sanitary, diaphragm pump is equipped with flap valves designed for pumping big solids – in this case champignons – in the food industry.

The new design of flap valves is more hygienic and easy to clean than previous generations.

The pump performance is excellent both for small and big (about 70-80mm) champignons however, the efficiency of pumping is bigger for smaller ones. According to the customer requirements over 95% of the mushrooms are intact after the pumping process.

Should you need similar solution or tailored to your specific needs please contact us at sales@tapflo.com or contact your local Tapflo dealer: http://tapflo.com/en/contact