CTI Industrial pumps

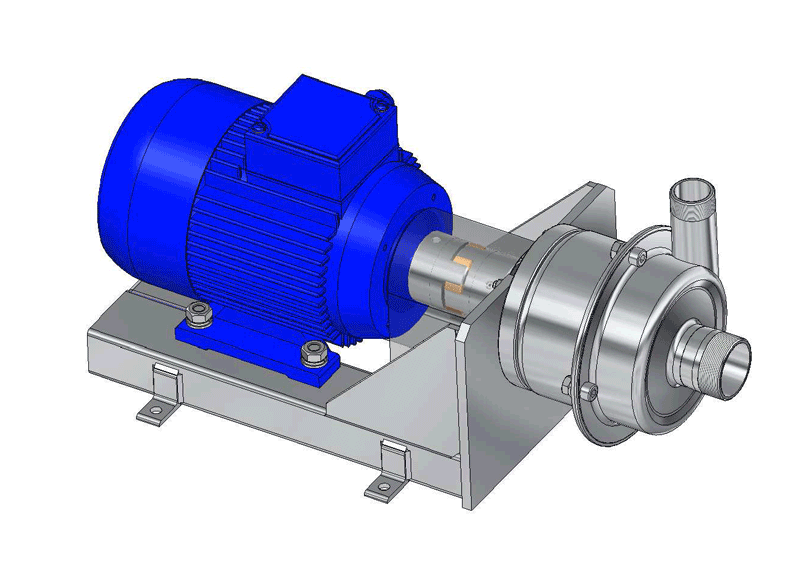

A very simple and ingenious design, with only 19 different components grants for easy and quick maintenance, in many cases completely maintenance free. The effect is very short down time and extremely low maintenance costs.

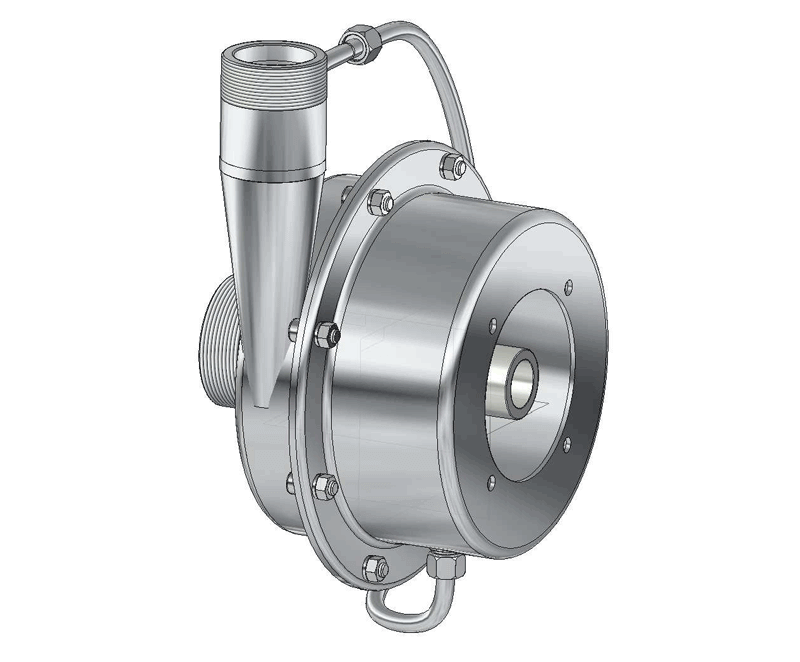

Standard single mechanical seal

provides a wide range of seal face materials – ceramic, graphite, SiC and o-rings in EPDM, FKM or FEP.

- The open impeller

is insensitive for solids (max 6 mm). Semi open impeller for heavy duty applications is available as option.

- Casing and impeller

components in glass blast stainless steel AISI 316L have a great compatibility with many mild chemicals.

- Flushed seal

Ideal when abrasive or sticky particles are present.This system where a small amount of the pumped product is recirculated from the discharge side to the seal chamber,will save the mechanical seal and seal chamber from being worn.

- Lubricated seal

A great option where there is a potential risk of dry running,or where the product tends to solidify or crystallize.An oil cup is connected to the mechanical seal chambe

- Long coupled execution

The perfect solution when pumping hot products like oil at temperatures up to 180°C.Complete pump unit mounted on baseplate, with coupling and guard.

- With 2900 rpm motor:

► CTI AA-03 7 m3/h, 10 m

► CTI AA-05 12 m3/h, 10 m

► CTI BB-07 17 m3/h, 11 m

► CTI CC-15 19 m3/h, 22 m

► CTI CC-22 34 m3/h, 22 m

► CTI CE-22 20 m3/h, 31 m

► CTI DD-40 50 m3/h, 22 m

► CTI DF-40 28 m3/h, 35 m

► CTI EF-55 42 m3/h, 35 m

► CTI EG-55 30 m3/h, 47 m

► CTI EF-75 60 m3/h, 35 m

► CTI EG-75 35 m3/h, 47 m

- With 1450 rpm motor:

► CTI AA-024 7 m3/h, 2.7 m

► CTI BB-054 9 m3/h, 2.8 m

► CTI CC-114 18 m3/h, 5.5 m

► CTI CE-114 22 m3/h, 7.7 m

► CTI DD-224 25 m3/h, 5.5 m

► CTI DF-224 34 m3/h, 8.7 m

► CTI DG-224 42 m3/h, 12.0 m